Tunneling, Aggregates & Mining Dewatering Processes

Hiller machines provide world-class standards for of high-performance decanter centrifuges on a wide variety of aggregates, tunneling, mining and mineral, dredging, and fluid recovery applications. In these demanding environments where reliability is of the highest importance for un-hindered continuous processing, increasingly strict environmental legislation and rising landfill costs make performance equally important. The versatility and performance of Hiller DP and more specialized DDF high performance centrifuges make them the first choice for dewatering of spent bentonite slurries in tunnel drilling as well as providing optimal solutions for many other related and demanding applications:

- Removal and dewatering of fines from un-weighted or pre-processed mud in tunneling applications

- Recovery of barite from weighted mud in vertical geothermal well drilling applications

- Removal and dewatering of fines from un-weighted or pre-processed mud in vertical geothermal well drilling applications

- Dewatering of sludge from quarries and lime stone slurries

- Dewatering of sludge from cutting and grinding of rock, concrete, and ceramics

- Dewatering of sludge from sand and gravel washing

- Dewatering of sludge from the construction of foundations

- Dewatering of sludge from soil remediation

- Dewatering of sludge from lagoon dredging

Hiller DDF centrifuges fulfill the requirements of these applications with a high degree of reliability providing minimal down time and maximizing through-put. Hiller units are equipped with the most powerful drive system on the market producing the highest possible cake dryness and shear strength. Plus the hydro-dynamically optimized machine design reduces power and polymer consumption for lower operating costs. The machines include heavy duty wear protection systems for long service life maximizing the time between wear repairs. And the Hiller centrifuges feature a service friendly design, meaning quick and easy maintenance in the field.

Tunneling: Tunnels are an increasingly important element in today's infrastructure. Not only are they used to provide an easy crossing through mountainous regions for road and rail-bound traffic. Increasingly they are also used in urbanized areas to augment over-loaded roads, to provide quicker routes through crowded cities, and to reduce noise and pollution impacts on residents.

Other uses include traffic links across waterways, as well as for collection and attenuation of storm water or wastewater peak flows. Modern tunnel boring machines (TBM) can have diameters of 14 meters and more enabling civil engineers to design multi-purpose tunnels, in order to provide maximum economic and environmental benefits. In recent times, the technological trend for tunnel boring machines has increasingly moved towards the Hydro-shield technology.

For over 10 years HILLER decanters have not only been used in horizontal drilling for the development of traffic routes and the construction of roads, railroads, and metro lines but also for drilling supply and disposal tunnels for the management of water, waste water and energy to clean bentonite, barite, and drilling polymer scavenging when so-called hydro-shield driving techniques are applied.

Proven Hiller Decanter Centrifuge Tunneling Applications:

- Tunnel dewatering

- Micro-tunneling (HDD)

- Hydro-shield technology for mega tunnel construction

“Tunnel dewatering” is the latest field of application for Hiller high performance centrifuges. For this application natural water penetrations have to be pumped out from the tunnel and are then cleaned with specialized Hiller decanter centrifuges.

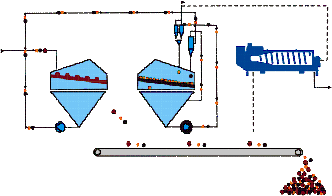

In Hydro-shield technology, the progressing tunnel is sealed from the tunnel excavation front by means of continuously recirculating bentonite slurry. At the same time, this slurry also serves as carrier for removal of the cuttings from the excavation front to the solids separation plant. In the solids separation plant, the cuttings are removed by means of screens and hydro-cyclones. The cleaned bentonite slurry is then ready to be recycled to the TBM. Even with changed slurry input and flow conditions in the decanter, Hiller’s new hydraulic drives offer a wider speed range with higher oil output allow for the processing of slurry quantities 20% to 50% higher than usual.

Depending on the properties of the soil where the tunnel is being drilled, very fine cuttings are accumulating in the bentonite slurry and thereby its properties are increasingly affected over time, in spite of the mechanical removal of cuttings mentioned afore. This negative effect can be monitored by measuring the density of the slurry. When the slurry density has risen above the acceptable limit, some of the slurry inventory is discarded and replaced with fresh bentonite slurry, in order to maintain the density in the system at the desired level. After having passed through the normal mechanical treatment, the discarded slurry is fed to a decanter centrifuge system for separation and dewatering of the spent bentonite, i.e. the very fine cuttings plus the bentonite. The dewatered solids are then sent to land-based disposal, or are used with rougher cuttings while the clear water can be discharged to sewers and is recycled to the process.

- Dewatering of sludge from quarries and lime stone slurries

- Dewatering of sludge from cutting and grinding of rock, concrete, and ceramics

- Dewatering of sludge from sand and gravel washing

- Dewatering of sludge from the construction of foundations

Hiller’s experience and engineering expertise is also well known and proven for processing mineral slurries and other specialized mining and aggregate applications. This experience includes supplying large size Hiller decanters centrifuges in containerized systems and multiple unit plant configurations.

Given increasing environmental concerns and greater emphasis on water conservation and recycling the use of mechanical separation technology with centrifuges has become increasingly accepted in mining and quarrying where large quantities of water are used for a variety of processes. These processes generate a high content of fine particles that must be separated.

Aggregates such as sand and gravel are mined and the unwanted components are typically removed in a separation process where the gravel is sieved and separated in different size ranges. In order to clean and classify the different gravel fractions, a significant amount of water is needed and the remaining fine sediment is usually pumped into lagoons, ponds or clarifiers which must later be dredged, pumped or drained to separate and dewater the accumulated material.

Limestone, marble and granite are also quarried in large volumes, which are further cut into dimension stone slabs and or pieces. These processes involve sawing and or abrasive cutting techniques which are dependent on water for cooling and carrying away the fine particles. The most efficient, economical and environmentally conscious systems are designed to clean the water to an acceptable level for recycling back to the process, often requiring settling of the fine particles using lagoons, clarifiers or tanks. However, utilizing a Hiller decanter centrifuge accelerates the separation process reducing the time factor and necessary water volume as well as saving space with a smaller required footprint.

Recycled aggregate is defined as aggregate resulting from the processing of inorganic material previously used in building or highway construction such as concrete, masonry mortar, floor pavement, lime, and other such materials. These materials are often recycled by further crushing, sorting and washing to produce a clean aggregate for re-use.