DAF Sludge Dewatering

Dissolved air flotation / DAF systems are commonly used in a variety of processing applications including food and dairy, meat, fish and poultry rendering, and waste vegetable oils applications to remove suspended solids, fats, oils and greases from a variety of wastewaters. DAF systems are also used for wide variety of industrial, manufacturing, oil and gas drilling, plus marine waste water treatment applications.

The high process rates, small footprints and operational flexibility are often an advantage in these applications. DAF systems inject micro bubbles into the waste steam which attach to the solids and float them to the surface where they are skimmed off. However one of the more common issues with a DAF system is the mess associated and disposal cost and with handling the skimmed off waste solids.

The Hiller range of decanter centrifuges are an effective and well proven equipment solution for dewatering the typically wet, sloppy solids skimmed off many DAF processes and wastewater systems. Using a decanter centrifuge to dewater DAF sludge can provide both tangible and intangible benefits and cost savings such as:

- Reduces total disposal volume by as much as 70%

- Produces stackable cake like sludge with no free liquid

- Reduces handling costs with less sludge volume and weight

- Increases options for sludge disposal

- Less mess and associated clean-up

With a wide capacity range of liquid / solid separating centrifuges and process options, Hiller-US can help you realize the above benefits. Hiller offers both two phase and three phase decanter centrifuges. In select applications three phase decanter centrifuges can provide the added benefit recovering free fats and oil phases from DAF sludges maximizing the return on investment.

Given the wide variety of DAF sludges and treatment programs Hiller-US would typically recommend on-site application testing to determine optimal equipment size, dewatering results and process parameters. For onsite application testing HILLER-US in Austin Texas area maintains a centrifuge pilot test unit. The portable system features a full-scale DP45 production model centrifuge mounted in a 53-foot trailer with all the system controls and ancillary equipment such as pumps, polymer systems, and sludge auger as well as connection hoses for a complete set-up. HILLER-US also has a smaller skid mounted DP26 with all the system controls and ancillary equipment such as pumps, polymer systems, and sludge auger as well as connection hoses for a complete set-up.

The typical one-week test program specifically evaluates the capacity of the centrifuge on a representative material. The purpose of this pilot study will be to investigate performance, provide operational data, and develop treatment experience with the centrifuge process. Test data is then summarized.

The test program will typically consist of a series of predetermined test runs designed to evaluate the cause-effect relationship between certain key performance parameters:

- Optimum polymer type

- Throughput vs. cake solids

- Polymer vs. cake solids

Hiller-US will also assist customers with the proper application set-up and installation parameters required for maximizing process results. A common and basic process description would typically be described as follows:

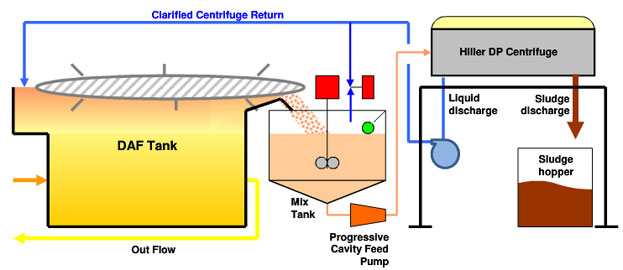

Process wastewater flows into the DAF tank and suspended solids float to the surface forming a layer or blanket of material, which is periodically or continuously scraped off and into a wet sludge holding tank and / or mix tank.

The mix tank gently agitates the solids into a homogeneous dilution of solids and liquid, which is then fed to the centrifuge using a progressive cavity feed pump.

If necessary an additional chemical additive may be introduced to help facilitate a more separable and dryer sludge cake. This is more prevalent with “fatty” solids.

A progressive cavity feed pump pulling from the bottom of the mix tank continuously feeds to the centrifuge and is controlled by a VFD to optimize pump speed and flow rate. The clarified centrifuge centrate is returned by gravity and / or balance tank with centrifugal pump back to the head of the DAF or collection pit / tank. The centrifuge continuously discharges the separated solids into a sludge hopper placed below the centrifuge.

A float switch opens a normally closed butterfly valve in the clarified liquid discharge line and adds re-circulated make-up water to the mix tank during low level conditions to maintain process conditions.

Top of Page