Animal Waste Processing

Hiller DecaPress DP model decanter centrifuges can be used on scrape or flush dairy and cattle feed lots, swine, poultry or other animal manure waste, lagoon sludges, or to dewater aerobic or anaerobic digester sludge. The centrifuges can also be used on fish waste, algae, and other wetland applications. These machines can be used for manure separation and /or thickening prior to anaerobic digestion as well as for dewatering after anaerobic digestion. A wide range of manure slurry feed rates, feed solids concentrations and feed materials can be centrifuged. Minor coarse prescreening or maceration is recommended for large and miscellaneous debris. No polymers or other additives required. Polymers can be used if solids removal levels in the high nineties are required.

The solids discharged from a HILLER DecaPress model horizontal decanter centrifuge will typically produce a stackable cake up to 32% dry material. And these centrifuges provide a high capture rate and will typically remove up to 90% of suspended solids in fresh flushed dairy or swine manure waste without using chemistry for flocculation and over 98% solids capture with polymer and or natural chemistries. Lower or higher removal rates possible with adjustments in feed rate, machine size, G force, or addition of chemistry.

Since removal of nitrogen and phosphorus are often important considerations it should be noted that approximately 25% of the nitrogen and about 50% of the phosphorus are removed coincidentally when at least 70% of the suspended manure solids are removed, on swine manure and up to 90% of phosphorous is removed when 98% of the suspended solids are separated from the dairy manure waste stream substantially removes the specific nutrients that cause the most problems in land irrigation/application and water pollution.

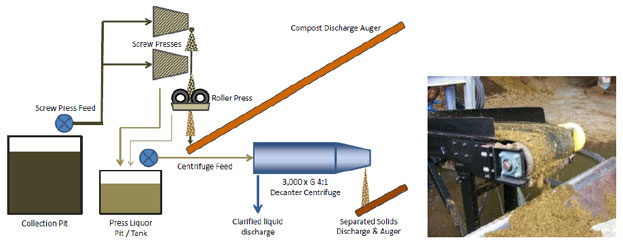

The following diagram depicts a simple mechanical dewatering cow manure process for concentrating waste from scrape dairy barns using compost bedding. Use of traditional and natural polymers can dramatically improve quality of centrifuge centrate discharge.

- Dewatering of scraped and / or flushed dairy, cattle, swine, poultry and other animal manure wastes, older lagoons sludges, plus dewatering digester sludges both aerobic and anaerobic

- Dewatering eliminates thousands of gallons of water from being applied to the fields which allows separated manure solids discharged from the centrifuge at up to 36% dry weight solids to be applied to the fields without overloading fields with nutrient loaded water and run-off

- Commonly separates 70 to 85% of suspended solids in fresh flushed dairy or swine manure waste without direct addition of chemical treatments although higher removal rates are possible with addition of polymers or flocculants (natural starch based polymers available) or by considering machine size and G force in relation to feed rate / retention time

- NITROGEN – PHOSPHORUS: Approximately 25% of Nitrogen and 50% of phosphorus removed when at least 70% of the suspended manure solids are separated

- DAF systems utilizing chemical polymers or flocculants can provide excellent water treatment results and relatively dry sludge cake when incorporating centrifuge technology to dewater the DAF sludge

- Decanter centrifuge offers maximum flexibility and adjustability to meet process requirements for solids discharge dewatering fresh flushed swine manure solids to approximately 30% dry solids or thickening within the 5% – 10% dws range with simple adjustments

- Easy to use and adjust with no full time operator required for continuous operation

- Wide range of manure slurry feed rates, feed solids concentrations and feed materials can be processed with coarse prescreening recommended to remove large debris including rocks, excess sand and other miscellaneous debris

- No filter media to blind-off

- No screens or filter cloths to replace

- All stainless steel product contact surfaces make the machines resistant to corrosion

- Full scale pilot size machines available for testing and all pilot test data can be directly scaled to production feed rates

For specific performance recommendations, please contact us, and if you don’t see your specific application mentioned, talk to us. We have the solution.

Top of Page