Sludge Dewatering

Sludge dewatering is the separation of a liquid and solid phase whereby, generally, the least possible residual moisture is required in the solid phase and the lowest possible solid particle residues are required in the separated liquid phase ("the centrate").

A typical example of this type of two-phase separation is the dewatering of sludge from municipal sewage plant or industrial waste water treatment. In this case, the residual moisture in the dewatered solids determines the disposal costs and the centrate quality determines the pollution load returned back to the treatment facility. Minimizing both must be achieved at the lowest possible cost, with the lowest possible polymer and energy consumption, with low maintenance costs and with the lowest possible number of required operating staff. In practice, the operator quickly realizes that there is no clearly defined operating point given daily and seasonal fluctuations; changes in system input or process configurations, as well as malfunctions of every sort always present new challenges that must be met. The Hiller DP model decanter centrifuge is a highly engineered piece of process equipment designed to separate insoluble suspended solids from a liquid. The centrifuge can be used to produce a relatively dry cake from the separated solids and are flexible enough to cope with a wide fluctuation in the feed material and still achieve excellent clarification and dewatering performance.

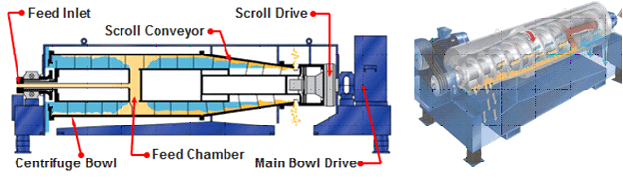

The centrifuge consists of a solid bowl, which rotates and contains the process. A screw conveyor, contained within the bowl, turns at a slightly different speed from the bowl.

The feed slurry is introduced into the feed chamber assembly by a stationary feed tube. It is accelerated up to speed in the feed chamber and discharged into the pond of the bowl through the feed ports.

The liquid flows from the point where it is introduced to the pond to the liquid weirs at the large end of the rotating assembly. As the liquid flows through the pond, the g force causes the solids to settle out of the liquid and to sediment against the bowl wall. This causes a blanket of solids to build up against the bowl wall.

The solids that build up against the bowl wall are pushed to the opposite end of the liquid discharge by the screw conveyor, which turns at a slightly different speed than the bow. The solids are pushed in the horizontal direction, up an incline and ultimately out of the liquid prior to being discharged from the bowl. Centrifugal force is constantly exerted on the solids in order to produce the desired solids in the discharged product.

The g force, pond setting, differential speed, flow rate, and polymer addition influence the clarity of the liquid discharged from the centrifuge. The liquid clarity is also influenced by the hydraulic throughput rate: the higher the flow rate, the poorer the liquid clarity. The exact relationship will be dependent on the nature of the feed material. The differential speed will also affect the clarity of the liquid. The lower the differential, typically the less turbulence in the liquid, and the cleaner the liquid being discharged (centrate). However, once the sludge blanket is overloaded and the screw conveyor does not remove the solids at the same rate that they enter the unit, the centrate quality will deteriorate.

The force that removes the solids from the liquid is the relative g force in the bowl. The faster the bowl turns, the greater the g force, and the greater the driving force to remove the solids from the liquid. The greater the g force, the better the centrate clarity will be.

The solids are also affected by the same parameters as the liquid. As the g force is increased, the force to compact the solids in the sludge blanket increases and the solids become thicker. The increased g force will release more free liquid and produce a drier cake.

The differential speed between the bowl and conveyor has a direct effect on the cake solids. As the differential speed between the conveyor and bowl is reduced, cake solids are increased. This increases the retention time and maximizes compaction in the solids.

The solids loading rate also has an effect on cake solids. In general, as the solids loading increases, the percentage of solids in the cake decreases. This is not a direct relationship, but results from the requirement to operate the conveyor at a higher differential speed to remove the solids from the bowl. This reduces the time for sedimentation in the bowl, which in return lowers the cake solids.

In addition to being used to improve liquid clarity, polymer also improves the dewatering characteristics of the sludge by agglomerating the solids and increasing the effective size of the solids. This is a variable that must be proven by field-testing.

Hiller DecaPress Decanter Centrifuge units are supplied with advanced controls for both variable speed bowl and scroll back-drive optimization making them easily configured to produce a wide range of sludge dewatering results. The Hiller DecaPress is very easy to set up while being extremely robust, stable, and reliable in everyday use, without the ease of use detracting from the quality of the operating results.

The decanter centrifuge will often produce better results than other dewatering equipment when secondary or biological sludges are present in the material to be processed. The primary reason for this is decanter centrifuges do not use filter media for separation and dewatering, which can often become blocked or blinded by biological sludges.

Dewatering Digested Sludge: As with activated sludge, decanter centrifuge operating parameters can be adjusted to thicken or dewater digested sludge. In most all dewatering applications when a polymer is used to aid separation the centrate clarity will typically look like the photograph with less than 200-ppm dws. For each site, it is important to optimize the use of polymer to be cost effective and still reach an acceptable goal for solids dryness.

Typical performance for dewatered digested sludge:

| Inlet solids | 2 to 4%-dws |

| Outlet solids | 28 to 33%-dws |

| Polymer required | 9 to 14-lbs/1000lbs-dws |

| Solids recovery | > 97% |

| Centrate quality | < 200-ppm |

To produce runny solids, speed up the conveyor drive and turn down the polymer feed rate to between 1 to 2-lbs/1,000-lbs dws. To produce a thicker solids consistency, slow down the conveyor drive and increase the polymer feed rate again. At 3 to 4-lbs/1000-lbs dws, thickened solids @ approximately 12%-dws will feature a consistency with a visible sign of free water but as the rate of polymer is increased, the solids become more homogenous.

By increasing the use of polymer dosage and controlling the decanter-operating parameters, the discharged solids become progressively drier. Per the photograph above @ approximately 18%-ds the solids can be handled satisfactorily with a mechanical shovel.

Top of Page